Considerations for a Successful Product Launch

When preparing for New Product Introduction (NPI) there are many considerations to be taken into account to ensure success for product launch:

Packaging Design: One of the biggest influences on a successful new product introduction and packaging process validation is the packaging design. There are four key factors that a client must balance without necessarily increasing the complexity and ultimately the cost of your pack.

Regulatory Compliance: Product packaging must adhere to the standards set in place by regulatory bodies. These requirements include labelling, data integrity, sterilization and shelf life.

Product Protection: Packaging must be robust enough to protect the product from damage potentially caused by environmental factors.

Commercial Requirements: This includes factors such as branding, usability and sustainability, and the production and material costs of packaging.

Processibility: Considerations such as material compatibility, ease of assembly and the ability to maintain production speeds without compromising quality of the final product.

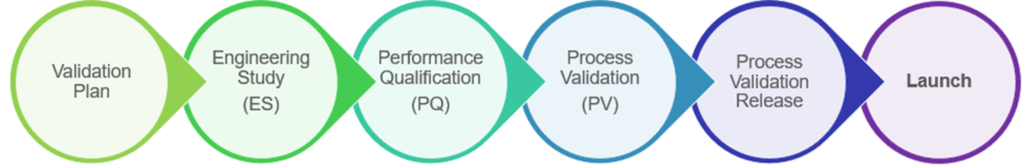

Validation Approach: Several factors can influence your validation strategy, such as packaging design, equipment, material, attitude to risk, and timeline. At Almac our approach to packaging validation is:

- Validation Plan – Details the approach to be taken to demonstrate a successful validation, defining critical quality attributes, equipment train, and packaging material.

- Engineering Study – This tests and defines machine parameters, ensuring the packaging material is compatible with the equipment, and performs a component fit test.

- Performance Qualification – Tests the full equipment train, processing at extremities of the operating ranges. This operates alongside the draft master batch record and provides a serialisation performance qualification.

- Process Validation – Tests the final commercial process in routine conditions with the approved master batch record. This can be for commercial or non-commercial batches.

- Process Validation Release – Defines the process specification and control strategy (PSC), equipment train, packaging materials, and QCAs. This releases the packaging process for routine commercial use.

- Launch – Once process validation release has occurred, the product can be launched.

Supply Chain Requirements

Supply chains can be complicated. You must be aware of import and export requirements when moving product between jurisdictions. Other considerations are:

- Are there product testing implications?

- Are there restrictions on importing unapproved products?

– e.g. Pre-Launch Activities Importation Requests (PLAIR) - Does your supply chain need to be qualified?

– Route qualification

– Dummy shipments

– Distribution testing

New Product Introduction is complex with many considerations, but Almac can assist.

Find out more about our product launch and commercial solutions today.