Biocatalysis: An Efficient Processing Solution? We Think So!

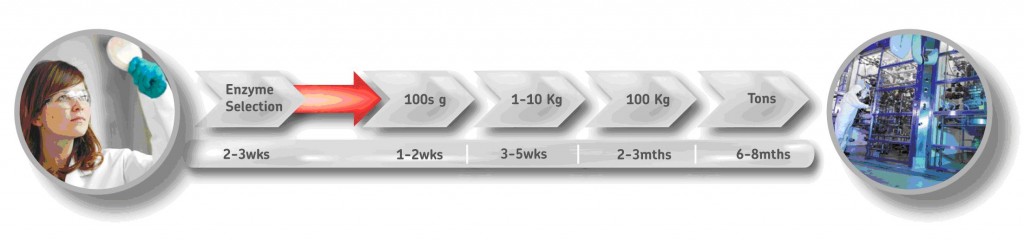

There is a common misconception that enzymes are unstable and expensive, work only under high dilution, and do not lend themselves well to scalable chemical processing. However, there are ever-increasing numbers of biotransformations being performed at a multi-tonne manufacturing scale, where biocatalysis has provided the most efficient processing solution. In addition, the timelines required to develop these bioprocesses are now comparable with chemistry scale-up, due to the availability of “off-the-shelf” enzymes, such as those in our selectAZymeTM platform.

There are a number of key factors involved in the development of a biocatalytic process such as substrate concentration, enzyme loading, solvent choice, product extraction and isolation. Development work consists of investigating reaction robustness by stress testing each of the relevant parameters, taking the reaction to its limits and then setting the optimised conditions.

We have carried out bioprocesses to GMP standard in our manufacturing plant and tech transferred processes to our customers from mg to tonne manufacture.

Process Development of Biotransformations

We have extensive experience in biotransformation process development:

- Process development expertise in bioprocessing for scale-up including hydrolase, ketoreductase, transaminase, BVMO, nitrile hydrates, nitrilase, P450 and cyanide dihydratase enzymes.

- Development of bioprocesses using carousels for reaction optimisation with DOE software.

- Qualitative and quantitative analysis and identification by NMR, HPLC, LCMS, with ability for further analytical support when required (including, protein, protein fragment, endotoxin and cell debris analysis).

- Freeze drying and spray drying expertise for accessing formulated enzymes.

- Immobilisation of selected enzymes on to various supports such as resins and chitin to improve cost contribution of enzyme and minimise work up operations.

- Rapid column screening and selection for both chiral and achiral methods (GC / HPLC).

- High throughput screening of enzymes using HPLC with 96 well plate holders.

- Isolation and purification of compounds using Biotage, Prep LC (chiral phase / achiral (reverse phase C18).

- Development of alternative processes to batch reactions such as continuous processing (plug reactors / continuous flow).

Immobilisation Capabilities

Almac has expertise in immobilisation screening and scale-up of immobilised catalysts, as well as whole cell and isolated enzyme immobilisation. Our immobilisation techniques cover:

- Binding to a prefabricated support (carrier)

- Entrapment in organic or inorganic polymer matrices

- Cross-linking of enzyme molecules

- Application of immobilised enzyme under continuous flow processing