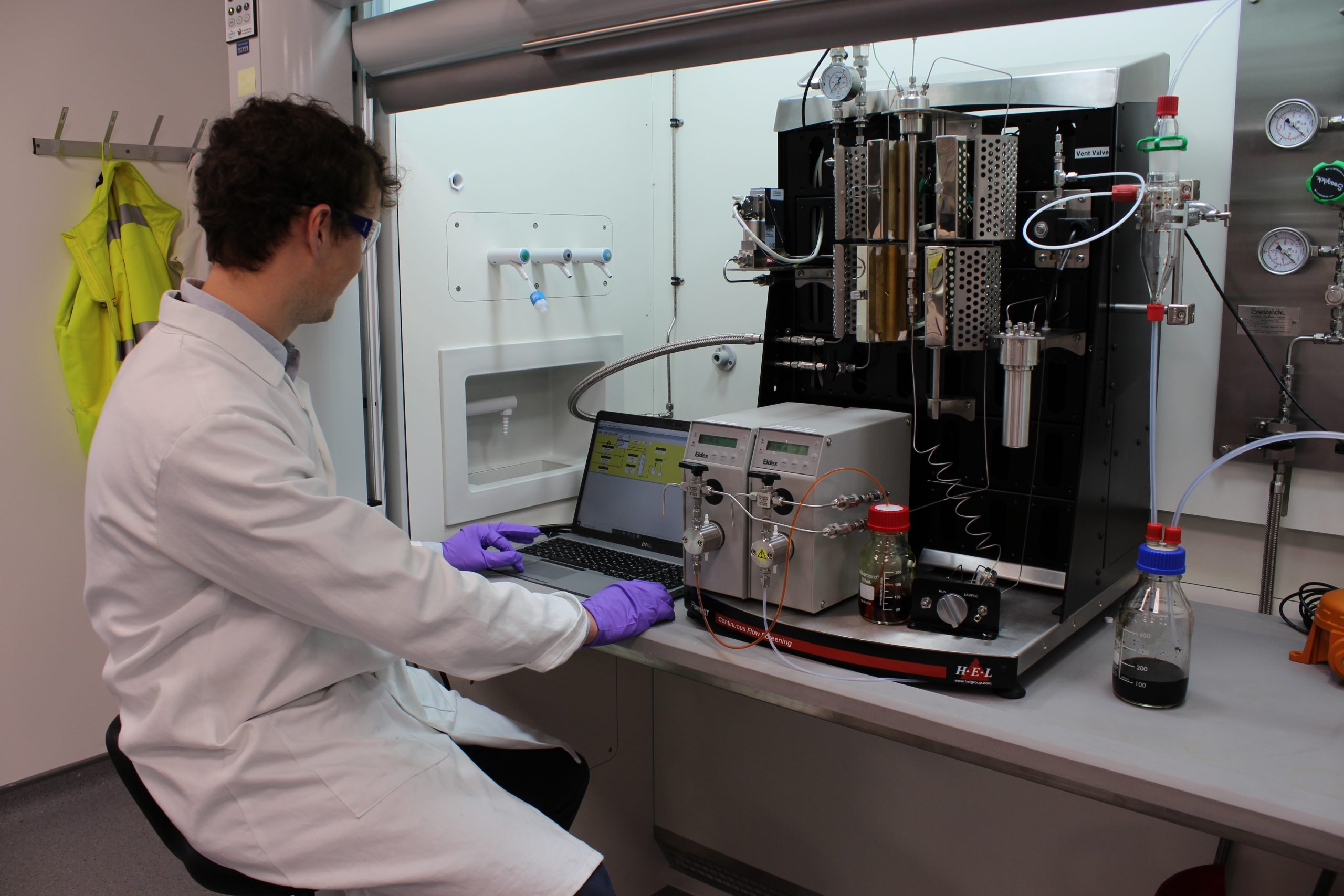

The purpose of Almac’s Flow Chemistry Platform is to provide superior solutions for our customers, utilising the best available technology to meet their demanding processing needs today, tomorrow and in the future.

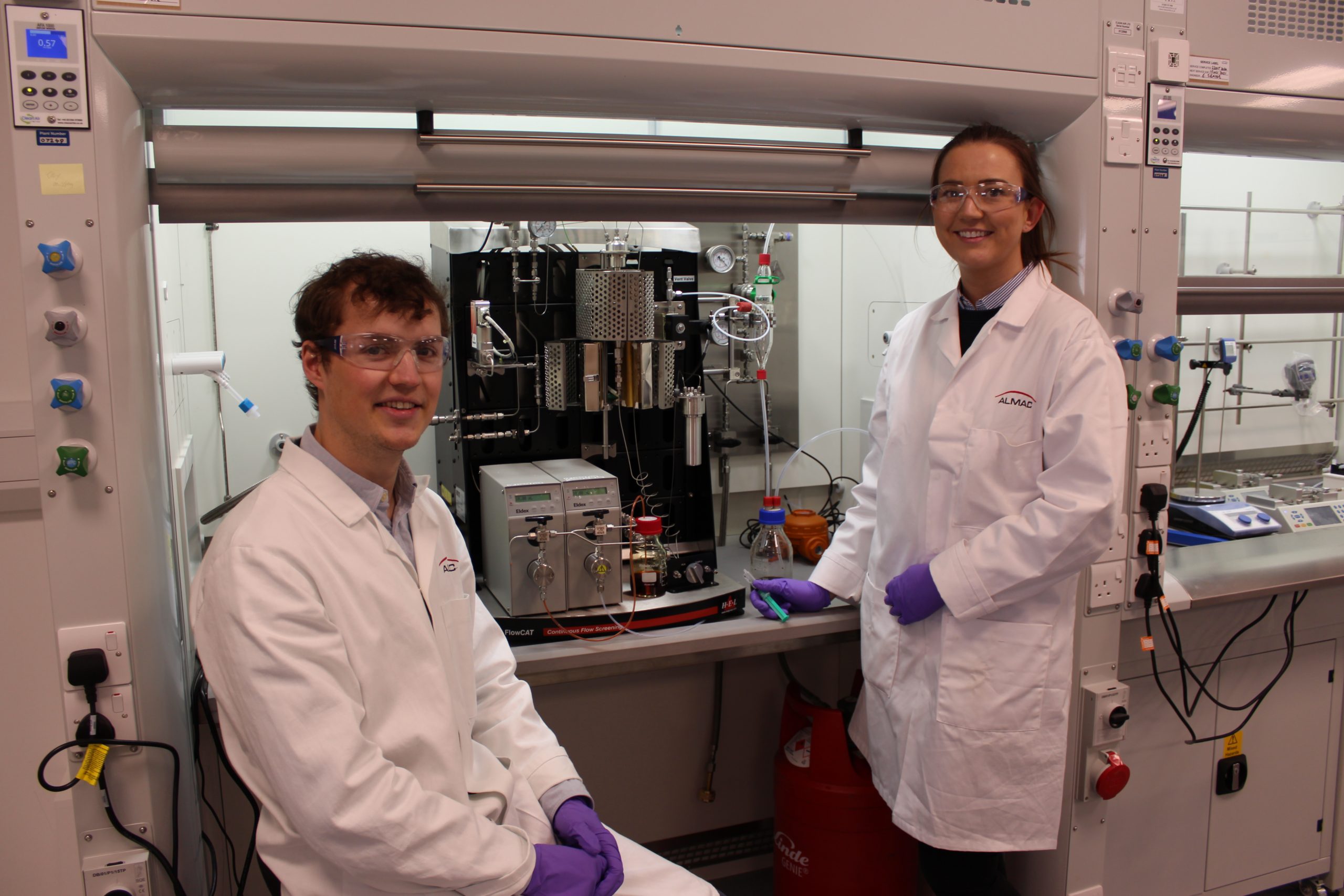

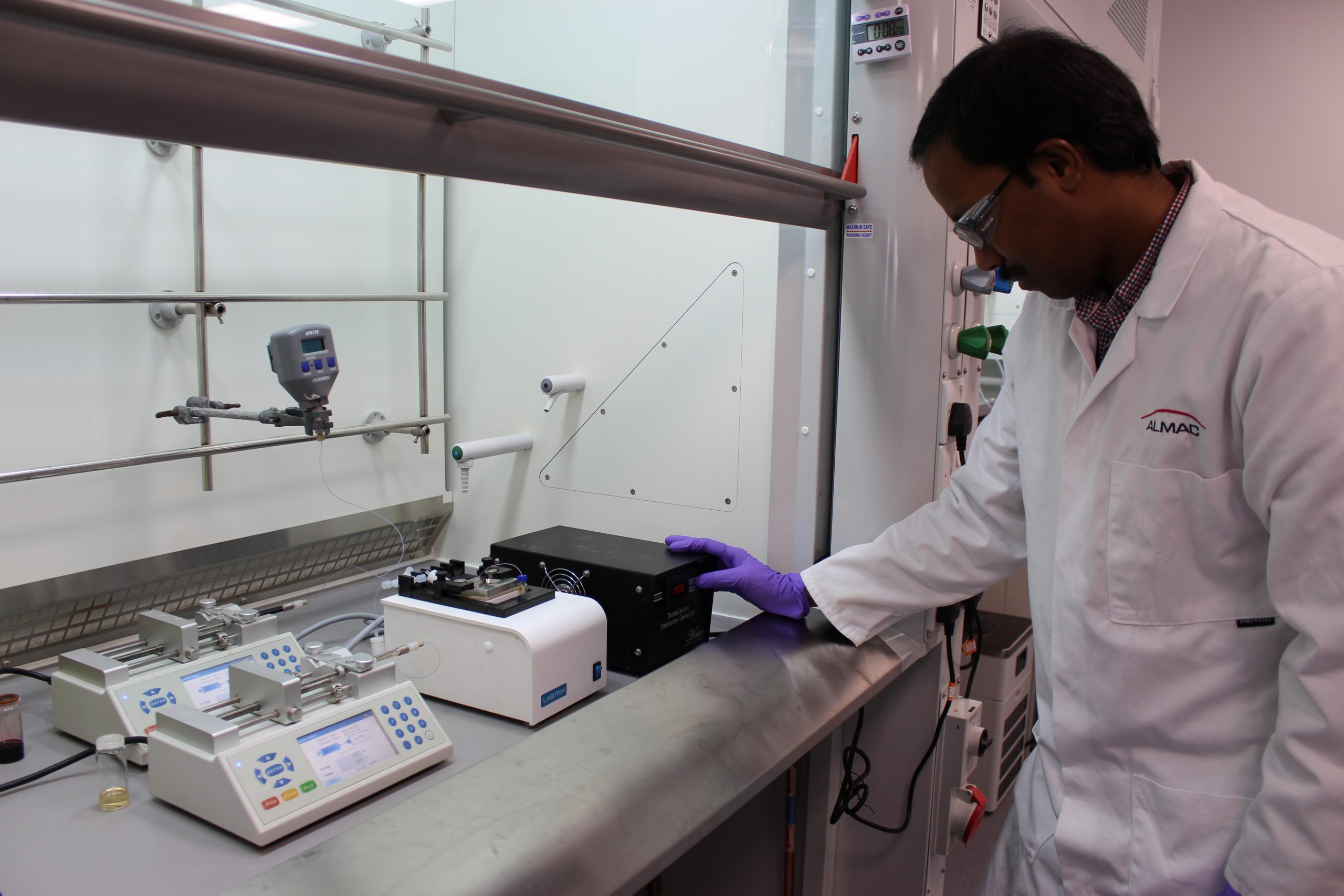

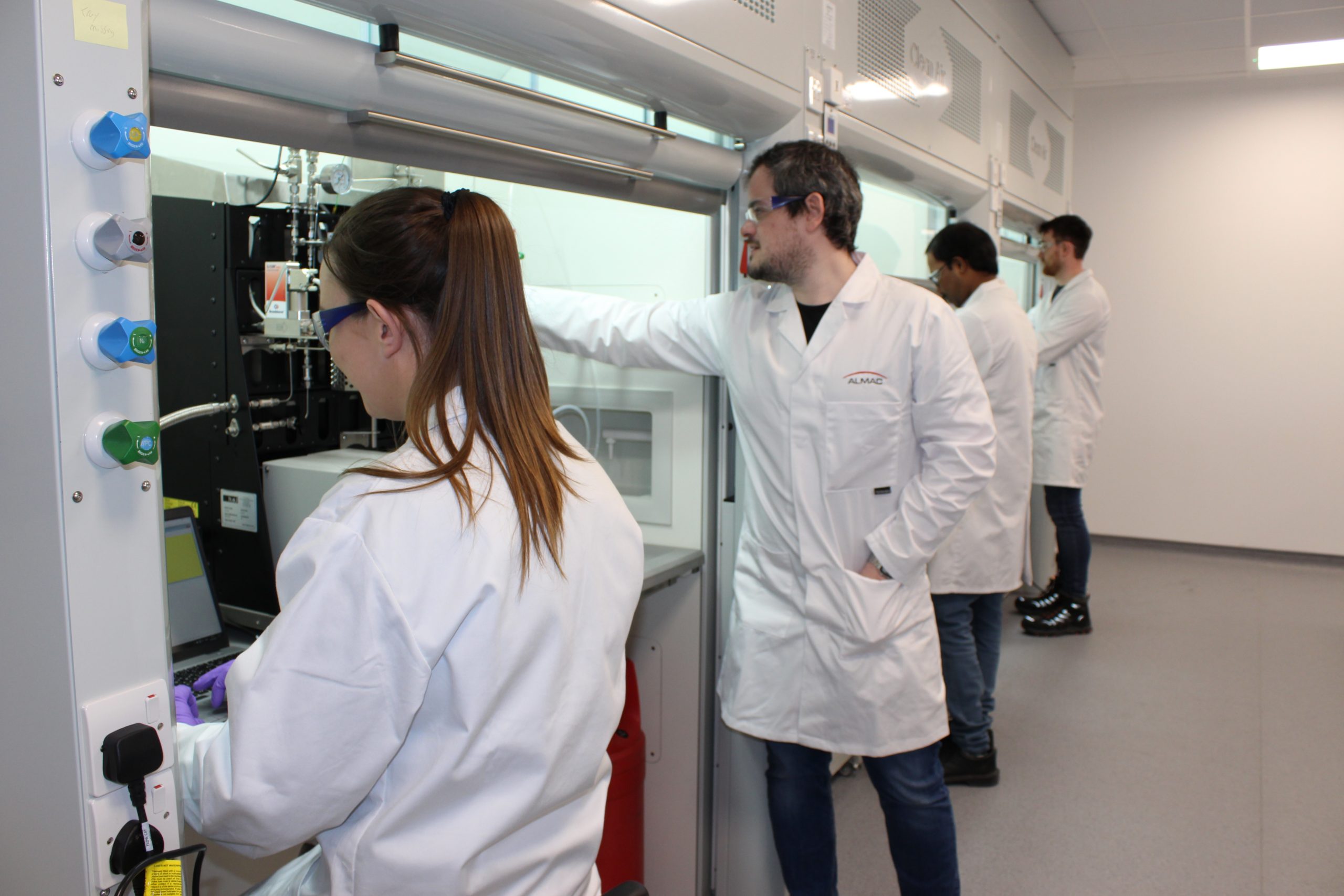

We have a multidisciplinary team consisting of both chemists and chemical engineers with extensive expertise in organic chemistry, suspension polymerisation, biocatalysis, enzyme immobilisation, process design and development for both GMP and non-GMP manufacture.

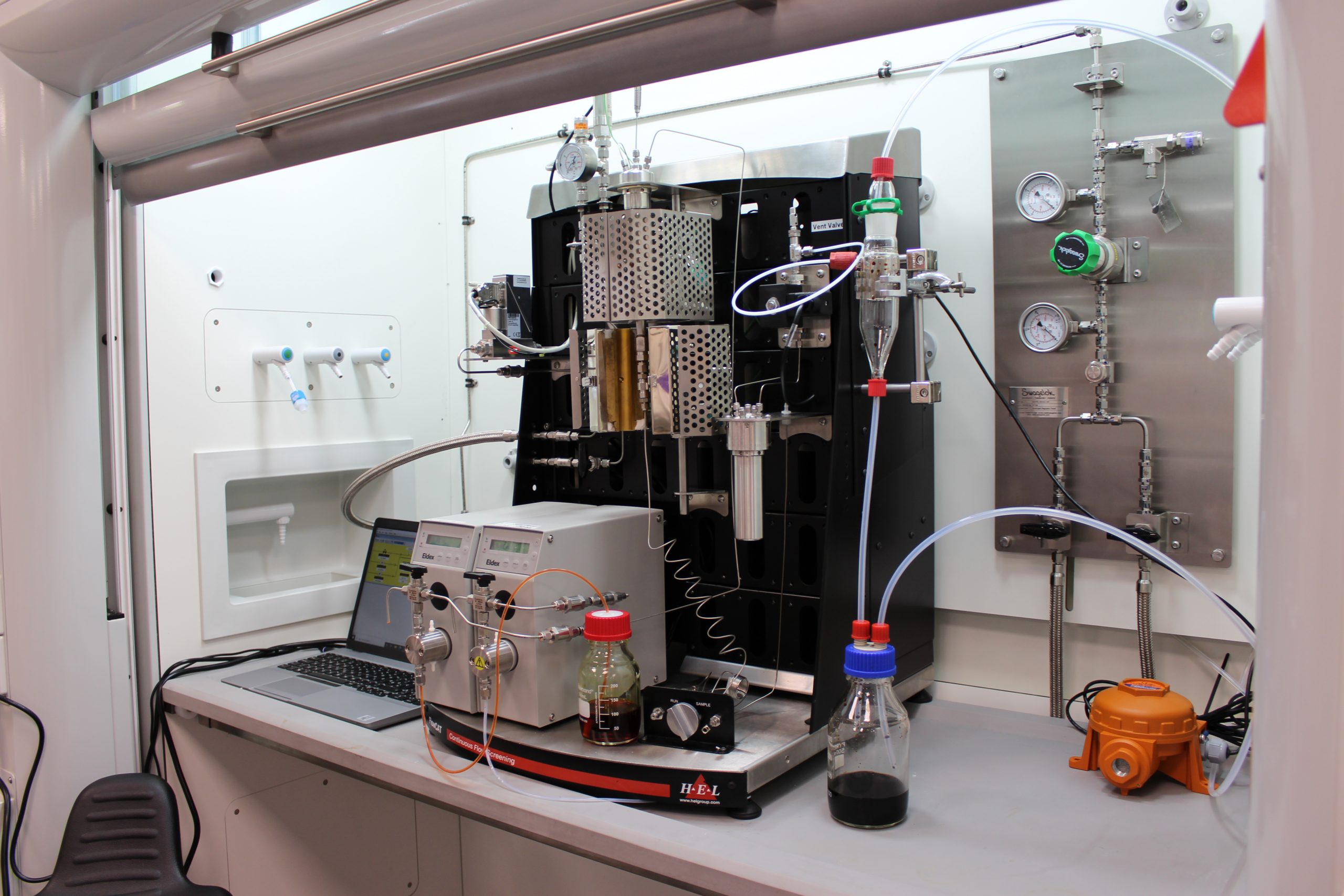

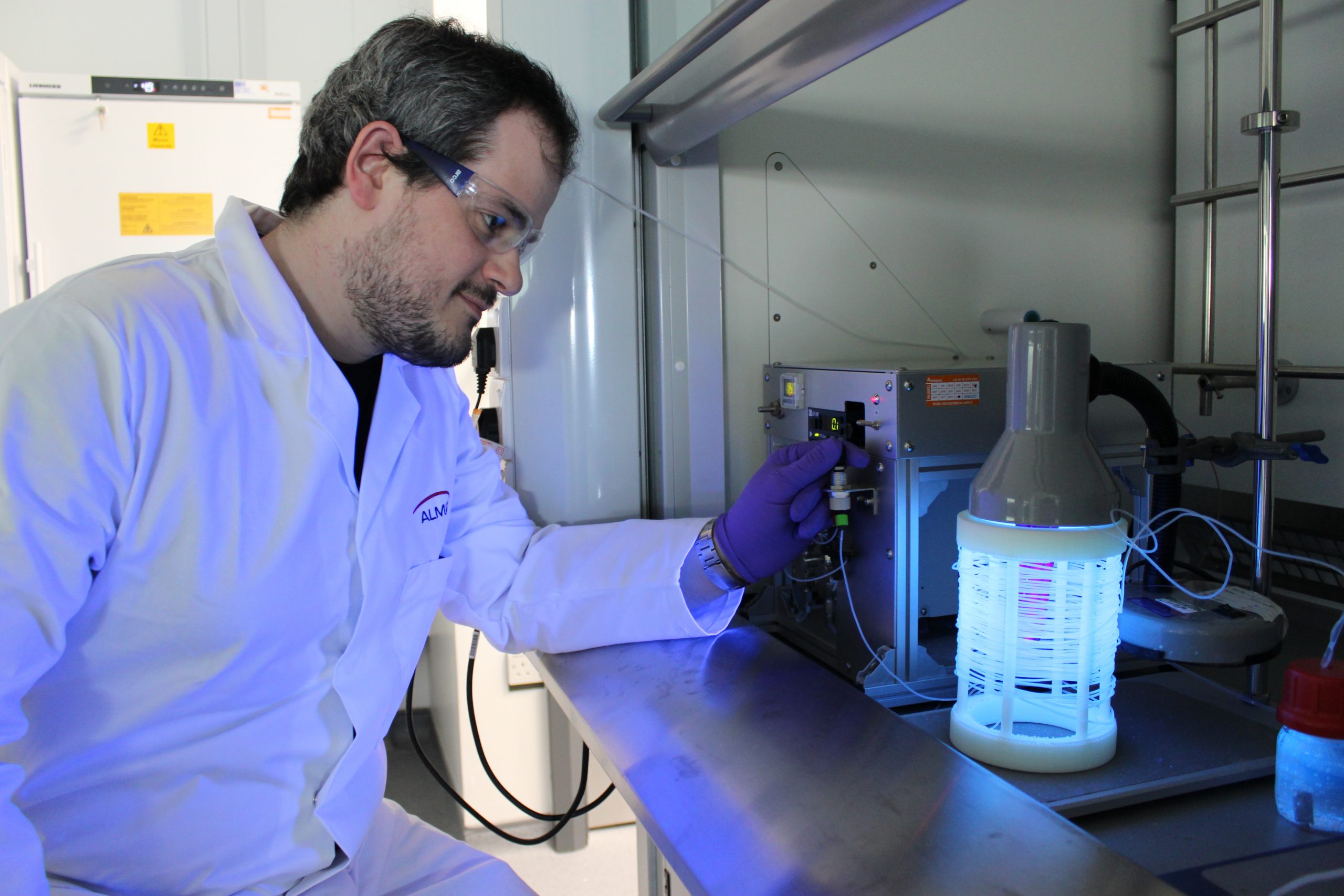

Almac has significant Flow Chemistry expertise including high pressure, high energy, oxidations and photochemistry.

Our team is closely linked to our biocatalysis, process chemistry and manufacturing chemistry groups, where flow chemistry is offered as an enabling technology with seamless integration into multi-step synthetic routes performed under conventional batch processing. Each member of the team brings expertise to complex processes procedures and can rapidly implement a flow process to significantly improve the yield and timelines of a multi-step synthesis.

We offer the following:

- Route invention using continuous flow technology.

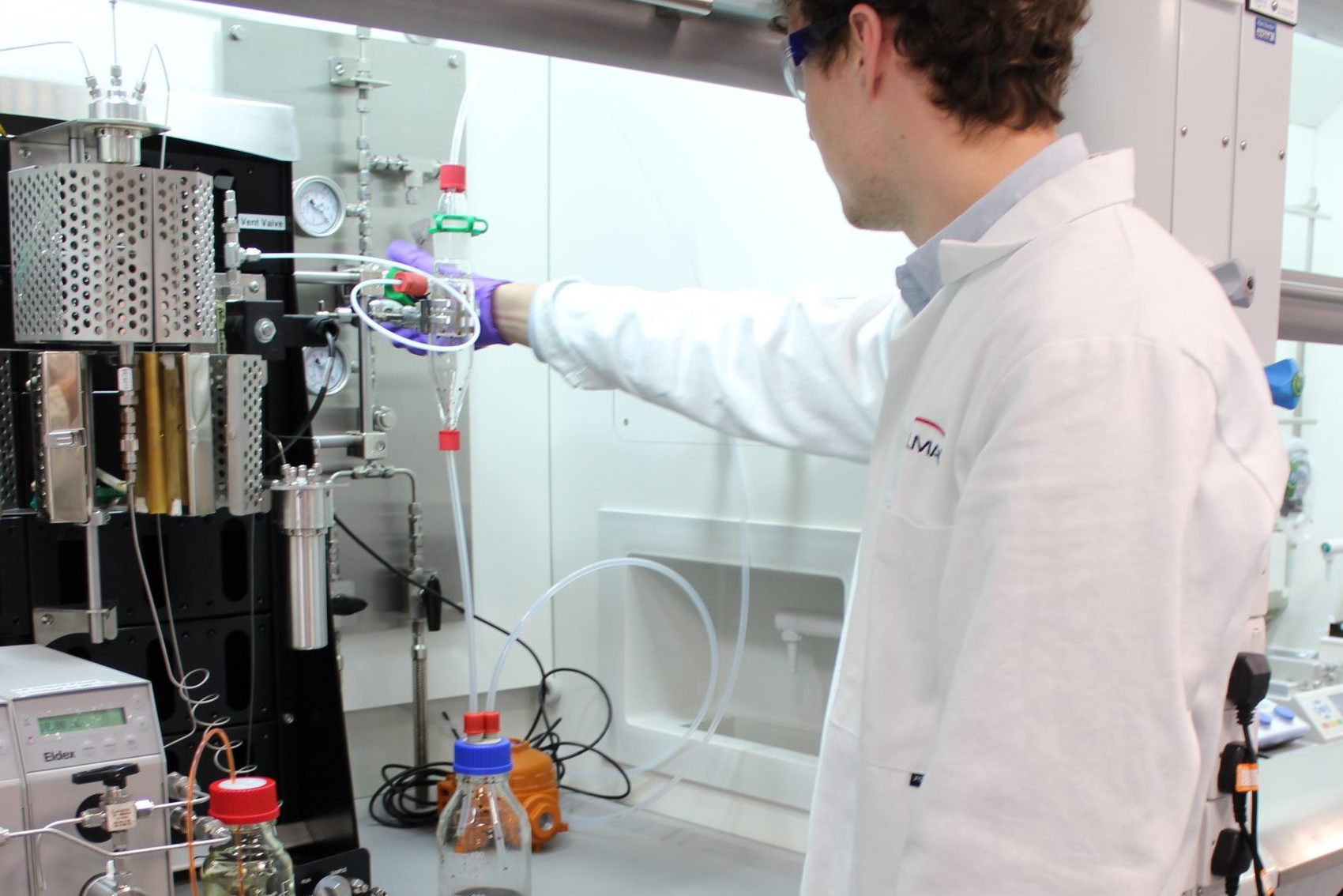

- Proof of concept studies and process demonstration.

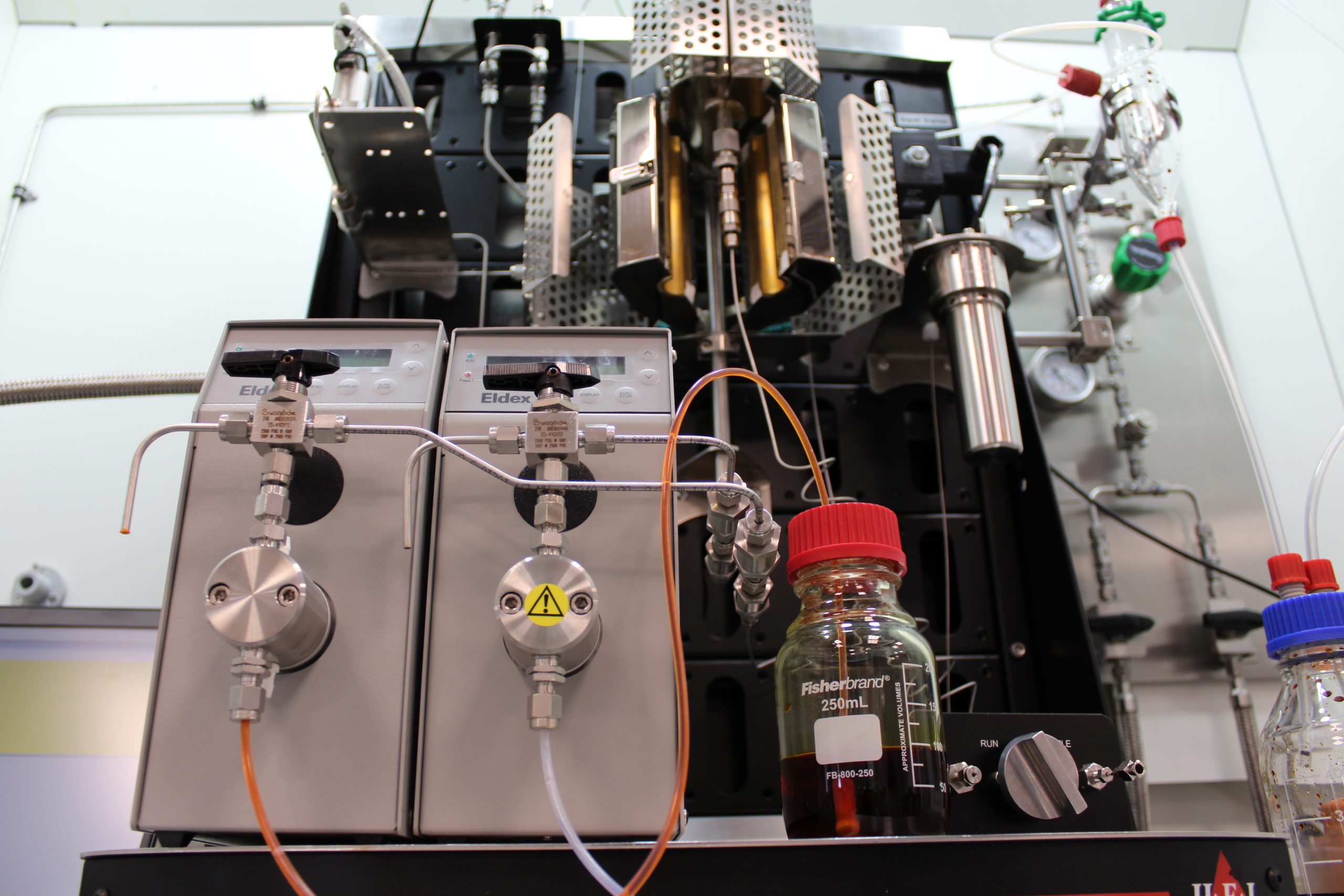

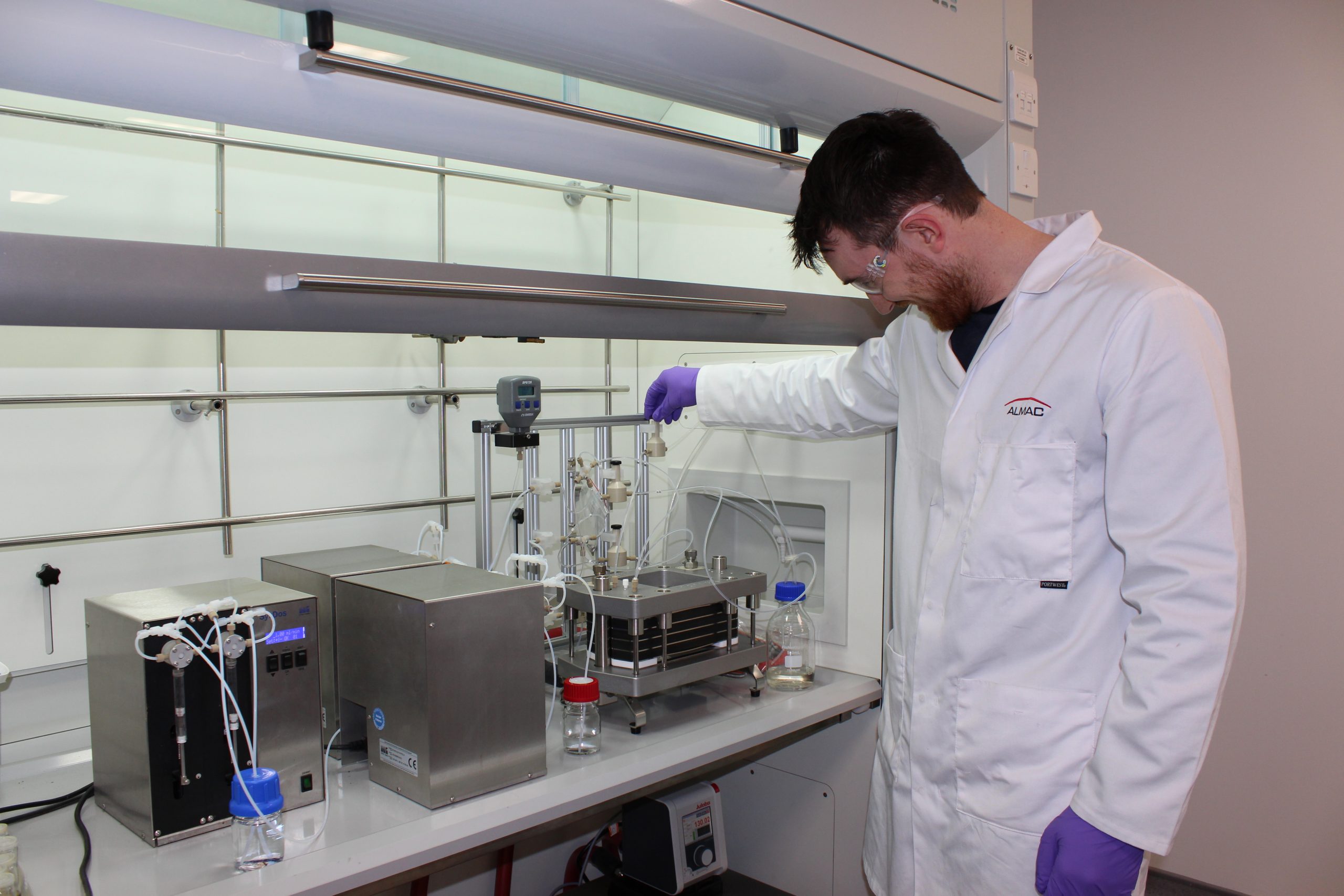

- Packed bed hydrogenations, rapid pelletised catalyst screening and process optimisation, custom built flow rig for rapid scale up.

- Flow as an enabling technology for suitable reactions in multi-step synthetic routes.

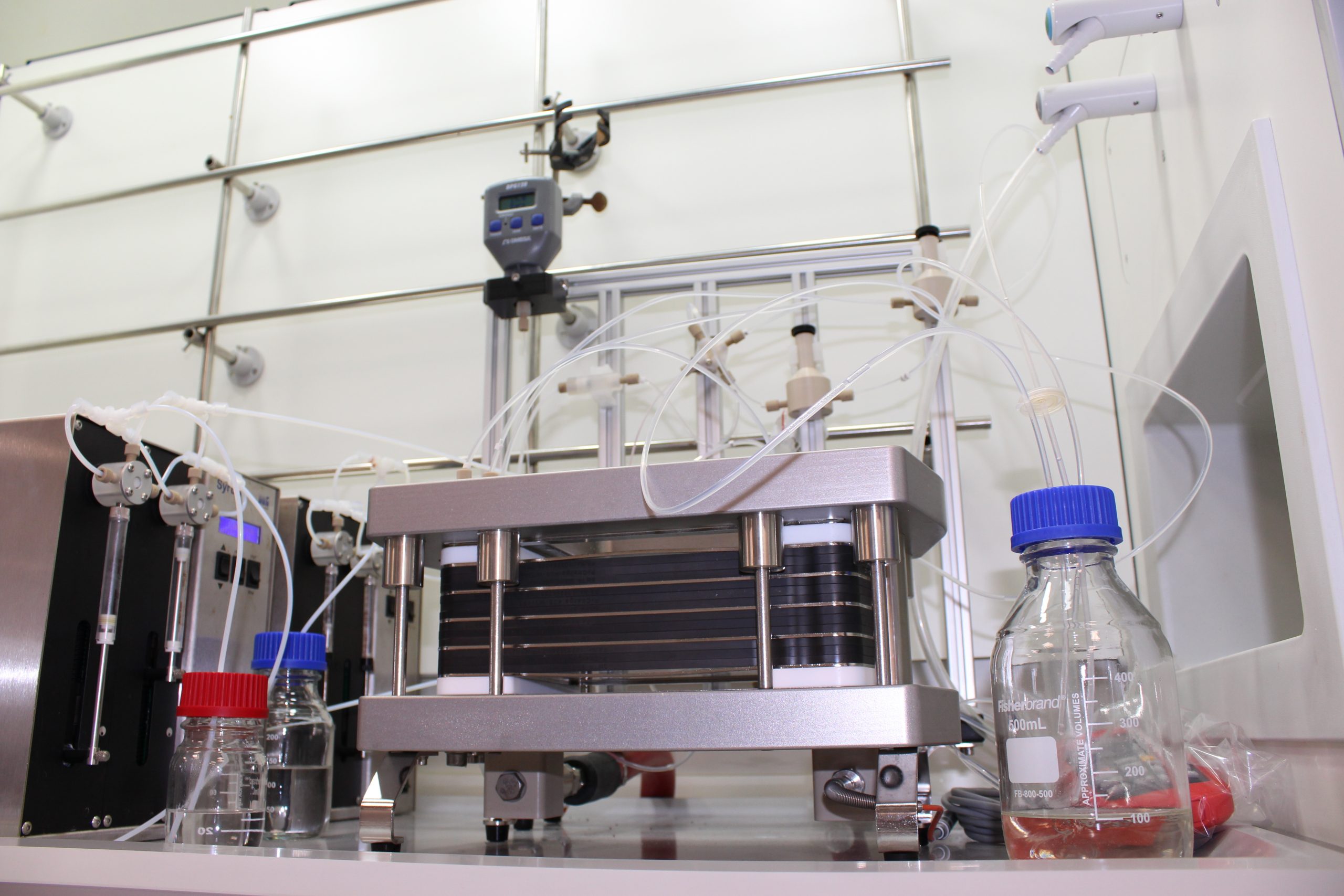

- Reaction validity in flow and process robustness within microreactor.

- Process tech transfer and product delivery.

- Lab scale production to low kgs.

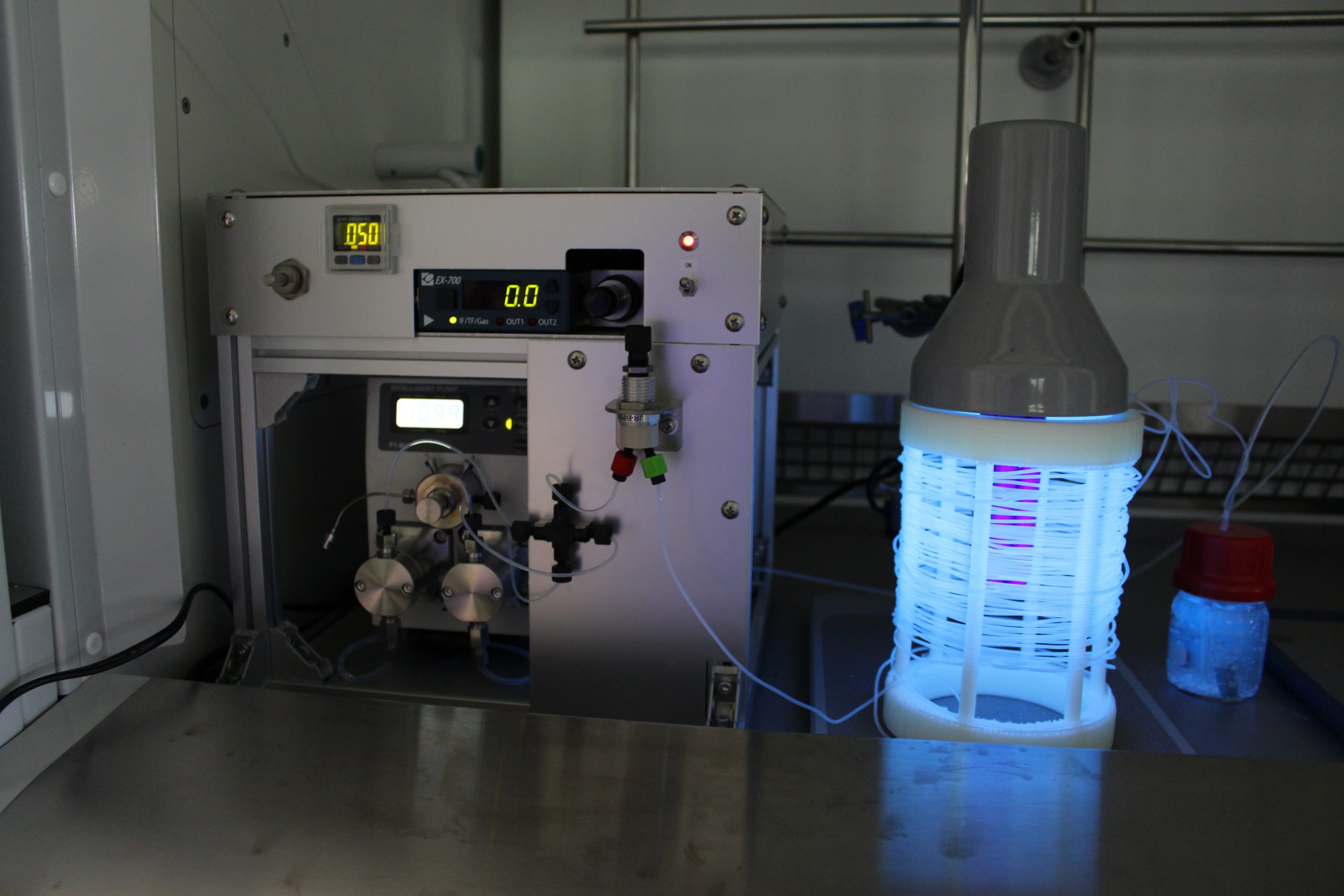

- UV-photochemical flow cell and LED’s.

- Development capabilities for both batch and flow and their integration.

- Enzyme immobilisation development and associated flow processes.

- Suspension polymerisation.

- UF/DF.

- Microbubble technology.