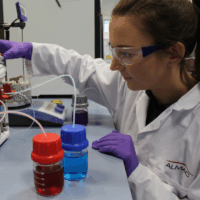

Crystallisation Process Development

As a world leader in pharmaceutical services, Almac delivers bespoke crystallisation development work programs for small molecules and peptides designed to provide a robust, scaleable, and transferrable crystallisation procedure to help accelerate clinical development and minimise risk in any downstream activities by eliminating batch-to-batch variability. The goals of typical studies include:

Impurity rejection / purge studies

Kinetics of nucleation and growth

Polymorphic form control

Maximising yield

Morphology engineering studies

Particle size control

Bulk density and powder flow improvement

Milling and micronisation studies

Isolation and drying processes

Control over residual solvent

Seeding protocol

Read the full article below to learn more.

View Resource

Almac API, Chemical Development, Analytical & Solid State Services

Almac Sciences provides integrated services from development to commercial scale of advanced intermediates and Active Pharmaceutical Ingredients (API).

We provide a range of services for small molecules (including highly potent) and peptides. We have a proven track record of saving time and cost through the integration of our services and application of innovative biocatalysis and technology solutions.

Learn More

We offer a full suite of analytical testing for a range of different product types including small molecules, peptides, biologics, conjugates, potent and controlled substances.

Our vast pool of scientific knowledge can help to overcome the analytical challenges that typically arise during drug development.

Learn More

You may also be interested in

This website uses cookies. By continuing to browse the site, you are agreeing to our

use of cookies

Agree