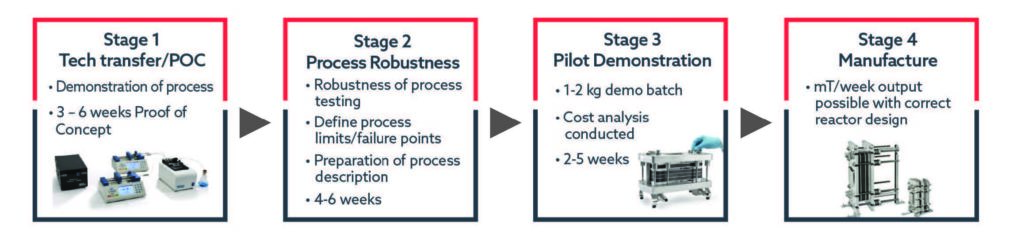

Almac’s flow chemistry team have implemented a four stage project workflow to ensure successful delivery of projects for our clients in acceptable timelines and at a competitive price.

Defined workflows ensure the development of robust, safe and scalable processes for multi-kg manufacture.

Stage 1: Proof of concept

Stage 1 involves confirmation of reaction validity under continuous flow including assessment of solubility of starting materials, reagents and products, as well as confirmation of product formation. Various parameters will be investigated such as stoichiometry, flow rates and temperature.

Stage 2: Process robustness

Stage 2 is a test of the process robustness to define safe operating windows for parameters as the process is further developed for scale-up. This stage also includes confirmation of flowability, hazard assessment and preparation of a process description (PD).

Stage 3: Pilot demonstration

With PD prepared, a demo batch of 1 kg can be carried out on intermediate equipment from lab scale to manufacture. This generates material for customer assessment and critical information for further scale-up if needed.

Stage 4: Manufacture

Manufacture will involve design and construction of a suitable flow rig, full safety testing around the process and delivery of the required amount of product with an agreed specification.

At the end of each Stage there is a Go or No Go decision made in agreement with the customer.