Almac is unmatched in its ability to manufacture clinical trial supplies and provide analytical support from its global locations in UK, Ireland, EU and Pennsylvania, USA.

Developing a drug is a costly and complex process where purity, safety and efficacy must be continually proven in order to meet strict regulatory requirements through clinical trials. Conducting analytical testing of drug product, comparator and placebo is an integral part of the clinical supply process and provides a valuable foundation for future drug development.

Analytical testing is a significant, critical, and sometimes unpredictable aspect of drug development. It not only has to be tailored to specific needs but delivered on time and within spec, enabling the successful launch of a clinical trial.

With over 50 years’ experience in providing analytical support to clinical packaging operations, we support your clinical trial analysis with additional data relating to:

Over-encapsulation (OE) activity

Over-encapsulation (OE) activity

When manufacturing an OE product for a clinical trial, analytical testing is required to model the dissolution profile of the new formulation of the drug. This is monitored compared to the original formulation to show similarity.

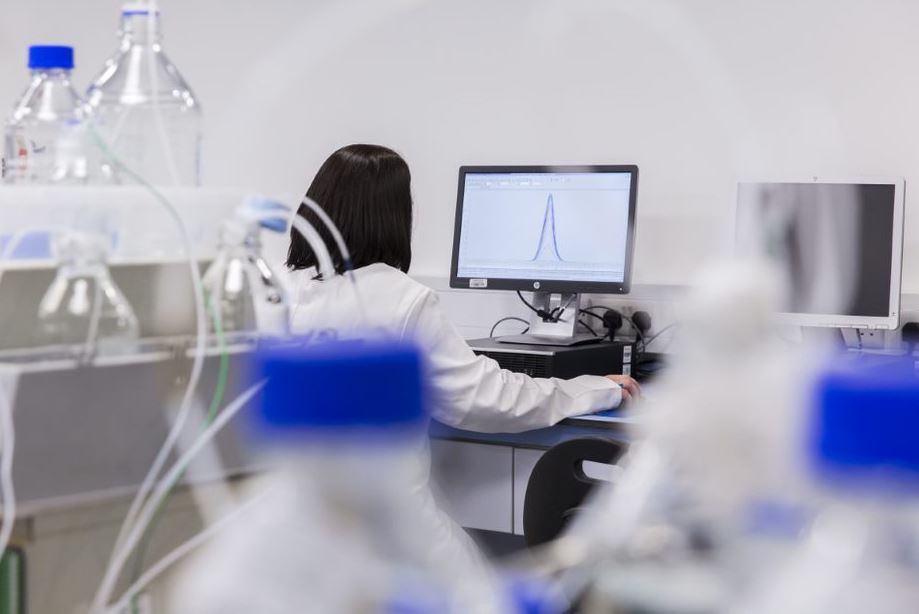

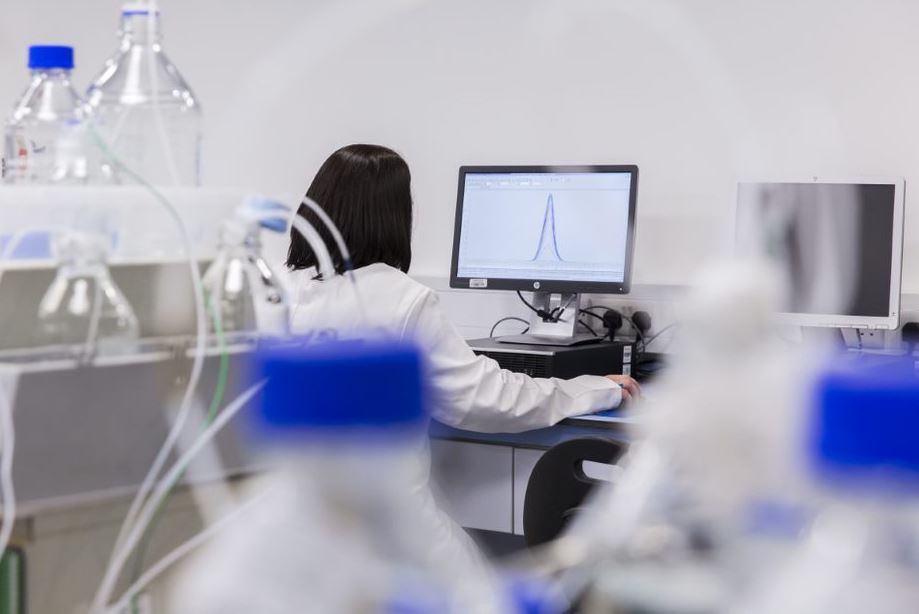

Dissolution testing is key to understanding how the drug acts in the body and informs on the bioavailability and therapeutic effectiveness of the drug. Therefore it is vital that a robust and accurate dissolution method is used. Almac works extensively in this area and has a range of different dissolution apparatus to ensure a suitable method can be applied in each case.

The Almac analytical team have been working with the clinical manufacture team for over 50 years, providing not only a technical advantage but a strong relationship between the two groups, who work closely together on each project. This symbiosis – both cultural and geographical – gives our clients an additional advantage when it comes to the delivery of projects.

Stability studies to support shelf life assignment

Stability studies to support shelf life assignment

Stability data is required for all finished products going onto clinical trials or to market, and additional data is often required to support new dosage strengths, formulations or packaging. Almac has extensive experience in both designing and performing stability studies and generating data to inform shelf life.

For OE products it is typical to perform stability on the newly OE drug, placebo and any comparator products used. The stability of these products is monitored under a range of ICH conditions to demonstrate the degradation profile (or lack thereof) for these products.

For new packaging, there is a requirement to demonstrate the products’ stability ensuring that it is fit for purpose. Almac offers a wide range of packaging options which can be placed on stability in our chambers in the UK, USA or Ireland.

In order to show the stability of these products, a robust analytical method is required. Almac has the expertise to work on a range of analytical methods which could be:

- Developed and validated at Almac labs

- Transferred in from client (or third party) labs

- Taken from the pharmacopoeas (USP, JP, EP) and used as written or adapted as required.

Identity testing to confirm active strengths or placebo tablets

Identity testing to confirm active strengths or placebo tablets

Identity testing is a critical part of the lot release process. Almac conducts a range of drug substance and product testing methods to ensure that the final drug product matches specifications. Techniques include:

- (U) HPLC (Ultra High-Performance Liquid Chromatography)

- Mass Spectrometry – LC-MS, LC-MS/MS

- NMR Nuclear Magnetic Resonance

- UV-Vis (Ultraviolet-Visible Spectroscopy)

- FTIR (Fourier Transform Infrared Spectroscopy)

Absence of active ingredient testing for converted placebo inhaler devices

Absence of active ingredient testing for converted placebo inhaler devices

Our inhaler blinding service allows the use of placebo inhalers in clinical trials. It is crucial that all traces of the active are removed from the inhaler and this is verified by testing ppm levels to ensure they are thoroughly cleaned. Almac has performed this testing on a range of different inhaler products as required by clients.

Release testing of packaged products

Release testing of packaged products

All pharmaceutical products must undergo rigorous testing to ensure they meet the quality and purity requirements of the relevant authorities. Release specifications include a range of tests depending on the drug structure and manufacturing process.

Our FDA, EMA and MHRA audited analytical laboratories provide a comprehensive range of product testing. Our product release service includes both chemical and microbial testing for innovator, comparator and placebo products. We tailor our release testing studies to client specifications which range from basic analysis through to more specialized techniques.

We adopt a flexible approach and each project is protocol-driven and tailored to our clients’ requirements. Our wide range of instrumentation enables us to deliver fit-for-purpose solutions to match your testing needs.

Our full suite of analytical testing for clinical trials covers a range of product types including small molecules, peptides, biologics, conjugates, potent substances and controlled substances.

Our FDA, EMA and MHRA audited analytical laboratories provide release analysis for drug substance and drug product commercial supplies. Release testing covers all activities associated with carrying out the analytical testing necessary for the release of the product into trials including:

•Analytical method transfer

•Appearance, assay and impurities, dissolution and microbial testing

•Issue of GMP certificate of analysis

Communication and scientific continuity are key, whether your analytical requirements are stand- alone or form part of a drug development or commercial manufacture project. Our analytical scientists routinely work with drug substance and drug product formulation scientists, forming an integral part of the project team. This means they can share data and easily coordinate planning and scheduling to deliver maximum efficiency.

Clients who use Almac to release drug substance and drug product in the EU & US benefit from shortened transfer time, cost savings and minimized disruption thanks to scientific and procedural continuity.